Research Paper

Critical Evaluation of Nanoparticle Tracking Analysis (NTA) by NanoSight

for the Measurement of Nanoparticles and Protein Aggregates

Vasco Filipe,

1,2

Andrea Hawe,

1

and Wim Jiskoot

1,3

Received December 9, 2009; accepted January 14, 2010; published online March 4, 2010

Purpose. To evaluate the nanoparticle tracking analysis (NTA) technique, compare it with dynamic light

scattering (DLS) and test its performance in characterizing drug delivery nanoparticles and protein

aggregates.

Methods. Standard polystyrene beads of sizes ranging from 60 to 1,000 nm and physical mixtures thereof

were analyzed with NTA and DLS. The influence of different ratios of particle populations was tested.

Drug delivery nanoparticles and protein aggregates were analyzed by NTA and DLS. Live monitoring of

heat-induced protein aggregation was performed with NTA.

Results. NTA was shown to accurately analyze the size distribution of monodisperse and polydisperse

samples. Sample visualization and individual particle tracking are features that enable a thorough size

distribution analysis. The presence of small amounts of large (1,000 nm) particles generally does not

compromise the accuracy of NTA measurements, and a broad range of population ratios can easily be

detected and accurately sized. NTA proved to be suitable to characterize drug delivery nanoparticles and

protein aggregates, complementing DLS. Live monitoring of heat-induced protein aggregation provides

information about aggregation kinetics and size of submicron aggregates.

Conclusion. NTA is a powerful characterization technique that complements DLS and is particularly

valuable for analyzing polydisperse nanosized particles and protein aggregates.

KEY WORDS: dynamic light scattering; liposomes; nanoparticles; nanoparticle tracking analysis; protein

aggregates.

INTRODUCTION

Most macromolecular drugs, such as proteins, peptides,

DNA and RNA, cannot be administrated via the traditional

oral route of administration, due to their susceptibility to

enzymatic degradation or low absorption efficiency (1,2). To

be effective, these drugs have to be delivered in most cases

via injection and/or through a drug delivery system (DDS).

DDSs not only protect the therapeutic drug or antigen

from degradation and/or increase their absorption, but may

also allow controlled release or the precise delivery to a

specifictarget(3). Common examples of DDS include

polymer-based particles, lipid-based carriers and virus-like

particles. Given that most of these DDSs are nanosized

colloidal particles, it is essential to have reliable character-

ization tools to ensure their quality and colloidal stability.

Another pharmaceutically important field that requires

adequate tools for the analysis of particles in the nano-

meter size range is the char acterization of protein aggr e-

gates. Therapeutic proteins are prone to several chemical

and physical degradation pathways, which often lead to

aggregation (4). The presence of aggregates in a protein

formulation compromises product quality and may lead to

unwanted immunogenicity (5). Thorough aggregat e char-

acterization is crucial to better understand the underlying

mechanism of aggregate-related immunogenicity and

ensure the quality of protein therapeutics. An accurate

determination of the size and size d istribution of aggre-

gated protein formulations is not straightforward, as

protein aggregates are typically very heterogeneous, with

sizes ranging fr om a f ew nanometers to several micro-

meters (6–8). Recently, the importance of analyzing sub-

visible protein aggregate s with sizes in the nanometer up to

the low micrometer ra nge ha s be come recognized (9).

The most commonly used techniques for the analysis of

nanoparticles and protein aggregates include dynamic light

scattering (DLS), scanning electron microscopy (SEM), size

exclusion chromatography (SEC), gel electrophoresis, asym-

metrical flow field-flow fractionation (AF4) and analytical

ultracentrifugation (AUC) (10–12). From the mentioned

techniques, DLS is the most user-friendly, and it yields

relatively accurate and consistent results that can be obtained

in a rather short period of time (10). Therefore, DLS has

become the preferred technique to routinely determine the

size of nanoparticles.

1

Division of Drug Delivery Technology, Leiden/Amsterdam Center

for Drug Research, Leiden University, P.O. Box 9502, 2300 RA

Leiden, The Netherlands.

2

Department of Pharmaceutics, Utrecht Institute for Pharmaceutical

Sciences (UIPS), Utrecht University, P.O. Box 80082, 3508 TB

Utrecht, The Netherlands.

3

To whom correspondence should be addressed. (e-mail: w.jiskoot@

lacdr.leidenuniv.nl)

Pharmaceutical Research, Vol. 27, No. 5, May 2010 (

#

2010)

DOI: 10.1007/s11095-010-0073-2

0724-8741/10/0500-0796/0

#

2010 The Author(s). This article is published with open access at Springerlink.com 796

Despite being a powerful and accessible tool, DLS is also

known to have several drawbacks, which are mainly inherent

to the principles of the technique. Particle size is determined

from fluctuations in scattered light intensity due to the

Brownian movement of the particles (13). The fact that the

intensity of the scattered light is proportional to the sixth

power of the particle diameter makes this technique very

sensitive to the presence of large particles (14). This can be an

advantage if the purpose is to detect small amounts of large

particles, but it can be a major drawback for accurate size

determination. Dust particles or small amounts of large

aggregates can impede the size determination if the main

component exhibits a distinctly smaller size (15).

Nanoparticle tracking analysis (NTA), which was first

commercialized in 2006, is an innovative system for sizing

particles from about 30 to 1,000 nm, with the lower detection

limit being dependent on the refractive index of the nano-

particles. This technique combines laser light scattering micro-

scopy with a charge-coupled device (CCD) camera, which

enables the visualization and recording of nanoparticles in

solution. The NTA software is then able to identify and track

individual nanoparticles moving under Brownian motion and

relates the movement to a particle size according to the

following formula derived from the Stokes-Einstein Eq. I (16):

x; yðÞ

2

¼

2k

B

T

3r

h

p

ðIÞ

where k

B

is the Boltzmann constant and x; yðÞ

2

is the mean-

squared speed of a particle at a temperature T, in a medium

of viscosity η, with a hydrodynamic radius of r

h

.

Our aim was to explore the potential of nanoparticle

tracking analysis (NTA) for the analysis of nanosized particles

and protein aggregates. A direct comparison with DLS was made

in order to reveal the advantages and pitfalls of a technique that

is now making its first steps in the field of characterization of

nanoparticles and submicron protein aggregates.

MATERIALS AND METHODS

Chemicals

Poly (lactic-co-glycolic acid) 50:50 (PLGA) and 4-(2-

hydroxyethyl)-1-piperazine-ethanesulfonic acid (HEPES) were

obtained from Sigma-Aldrich (Steinheim, Germany), chitosan

(deacetylation degree 92%, MW 120 kDa) from Primex

(Siglufjordur, Iceland) and egg L-α-phosphatidyl choline (EPC)

from Lipoid GmbH (Ludwigshafen, Germany). 1,2-dioleoyl-sn-

glycero-3-phospho ethanolamine (DOPE) and 1,2-dioleoyl-3-

trimethyl ammonium-propane (DOTAP) were supplied by

INstruchemie (Delfzijl, The Netherlands). Chloroform was

purchased from Biosolve (Valkenswaard, The Netherlands).

All other chemicals used were from Sigma-Aldrich (Steinheim,

Germany), unless mentioned otherwise.

Preparation of Polystyrene Bead Samples

Polystyrene nanometer standard beads with sizes of 60,

100, 200, 400 and 1,000 nm were purchased from Thermo

Scientific (Fremont, USA). They were diluted from the

supplied package in deionized water until the concentration

was acceptable for NTA measurements, i.e. between 10

7

and

10

9

total particles/ml. Thus, from the supplier’s recipient, a

1:30,000 volume based dilution was made for the 60-nm beads,

1:100,000 dilution for the 100-nm beads, 1:25,000 dilution for

the 200-nm beads, 1:2,500 dilution for the 400-nm beads, and

1:100 dilution for the 1,000-nm beads. All polystyrene bead

measurements were performed with these samples, either

alone or mixed at different volume ratios or number ratios

based on NTA particle counts, as stated in the results section.

The 100-nm and 400-nm beads mixture used for the

spiking experiments contained about 1.7*10

8

beads/ml. For

these experiments, 2 or 40 μ l of a suspension of 1,000-nm

beads (ca. 1.6*10

8

particles/ml) were added to 500 μl of the

100-nm and 400-nm beads mixture, which resulted in a

1,000-nm beads concentration of about 6.4*10

5

beads/ml and

1.2*10

7

beads/ml, respectively. The resulting number ratios

of 1,000-nm beads to the beads in the initial mixture was

1:267 for the 2 μl spike (small spike) and 1:13 for the 40 μl

spike (big spike).

Preparation of Drug Delivery Nanoparticles

N-trimethyl chitosan (TMC) with a degree of quaterni-

zation of 15% was prepared from chitosan and used to make

TMC nanoparticles, as described in the literature (17). In

short, TMC was dissolved in a 5 mM HEPES buffer (pH 7.4),

and pentasodium tripolyphosphate (TPP) was added under

continuous stirring to a weight ratio TMC:TPP of 10:1.8.

Nanoparticles were collected by centrifugation ( 30 min,

15,000 g) on a glycerol be d, to avoid aggregation, and

resuspended in 5 mM HEPES buffer (pH 7.4). The sample

was diluted 1,000-fold with deioniz ed water before the

measurements.

PLGA nanoparticles were prepared by an “oil-in-water”

solvent evaporation method, using polysorbate 20 as emulsi-

fying agent. Briefly, 1 ml of dichloromethane containing

50 mg of PLGA and 2 ml 1% (w/v) polysorbate 20 were

emulsified using an ultrasonic processor for 15 s at 70 W

(Branson Instruments, Connecticut, USA). The emulsion was

transferred to 50 ml of 0.02% (w/v) polysorbate 20 in water

and stirred at 50°C for 1 hr. The resulting PLGA nano-

particles were collected by centrifugation (8,000 g for 10 min)

and washed twice in distilled w ater to remove excess

polysorbate 20. The sample was diluted 2000-fold with

deionized water before the measurements.

Cationic liposomes were prepared by the film-hydration-

rehydration method and siz ed by sonication. In detail, a

lipid film was formed by s olvent evaporati on of a chloro-

form solution of EPC, DOPE and DOTAP in a rotary

evaporator at 37°C. To prepare 1 ml of liposome disper-

sion, a total amount of 28 μmol lipid was used at a EPC/

DOPE/DOTAP molar ratio of 4/2/1. The film was hydrated

in1mlof20mMHEPES,5%glucose,pH7.4,andthe

dispersion was equilibrated for 1 hr at room temperature.

The dispersion was then sonicated twice for 30 s, w ith 30 s

interval, using a Branson Sonifier 250 (Branson Ultr a-

sonics, Danbury, UK), with 3 mm microtip at 20 mW

energy output. The sample was diluted 10,000-fold with

deionized water before the measurements.

797Critical Evaluation of Nanoparticle Tracking Analysis (NTA)

All the buffers used in this section were filtered using a

0.22-μm PES low binding syringe-driven filter unit (Millex™

GP, Millipore, Ireland), and the absence/very low content of

submicron particles was confirmed by their visualization in

the NanoSight sample chamber.

Preparation of Protein Aggregates

A recombinant human monoclonal antibody of the IgG

1

subclass (IgG) was used for preparing IgG aggregates. The

IgG was formulated at a concentration of 1.0 mg/ml in 10 mM

sodium citrate (Merck, Darmstadt, Germany), 5% (w/v)

sucrose (Sigma-Aldrich, Buchs, Switzerland), pH 6.0. The

IgG formulation was filtered using a 0.22-μm PES low binding

syringe-driven filter unit. One ml of the filtered IgG

formulation was placed in 1.5-ml reaction tubes (Eppendorf,

Hamburg, Germany) and incubated for 15 min at 74°C in a

heating block (Eppendorf, Hamburg, Germany). The sample

was diluted 50-fold with the formulation buffer before each

measurement.

Recombinant human insulin (insulin) was formulated in

10 mM sodium phosphate, pH 7.4, and the formulation was

filtered using the same filter unit as for the IgG formulation.

Insulin aggregation was induced via a metal-catalyzed oxida-

tion reaction by the addition of copper chloride (0.04 mM),

followed by ascorbic acid (4 mM). The formulation was

incubated at room temperature for three hours, and the

reaction was stopped by the addition of 1 mM ethylenedia-

minetetraacetic acid (EDTA).

All the buffers used in this section were filtered using a

0.22-μm PES low binding syringe-driven filter unit, and the

absence/very low content of submicron particles was con-

firmed by their visualization in the NanoSight sample

chamber.

Dynamic Light Scattering (DLS)

DLS measurements were performed with a Malvern

Zetasizer Nano ZS (Malvern, Herrenberg, Germany) equip-

ped with a 633-nm He-Ne laser and operating at an angle of

173°. The software used to collect and analyze the data was

the Dispersion Technology Software version 6.01 from

Malvern. Five-hundred μl of each sample was measured in

single-use polystyrene half-micro cuvettes (Fisher Emergo,

Landsmeer, The Netherlands) with a pathlength of 10 mm.

The measurements were made at a position of 4.65 mm

from the cuvette wall with an automatic attenuator and at a

controlled temperature of 25°C. For each sample, 15 runs of 10 s

were performed, with three repetitions for all the polystyrene

beads and six repetitions for the polymer nanoparticles,

liposomes and protein aggregates. The intensity size distribu-

tion, the Z-average diameter (Z-ave) and the polydispersity

index (PdI) were obtained from the autocorrelation function

using the “general purpose mode” for the monodisperse

polystyrene beads, liposomes and polymer samples, the “multi-

ple narrow mode” for the mixtures of polystyrene beads and the

“protein analysis mode” for the protein aggregates. The default

filter factor of 50% and the default lower threshold of 0.05 and

upper threshold of 0.01 were used. The error bars displayed on

the DLS graphs were obtained by the standard deviation (SD)

of three or six measurements of the same sample.

Nanoparticle Tracking Analysis (NTA)

NTA measurements were performed with a NanoSight

LM20 (NanoSight, Amesbury, United Kingdom), equipped

with a sample chamber with a 640-nm laser and a Viton

fluoroelastomer O-ring. The samples were injected in the

sample chamber with sterile syringes (BD Discardit II, New

Jersey, USA) until the liquid reached the tip of the nozzle. All

measurements were performed at room temperature except

the live monitoring protein heat stress measurements (see

section below).

The software used for capturing and analyzing the data

was the NTA 2.0 Build 127. The samples were measured for

40 s with manual shutter and gain adjustments. The “single

shutter and gain mode” was used to capture the monodis-

perse polystyrene beads, the 60/100 nm beads mixture, the

liposomes, the TMC particles and the protein aggregates. The

“extended dynamic range mode,” which splits the capture

video into two videos with independent shutter and gain

settings, was used for all the other mixtures of monodisperse

polystyrene beads, the PLGA particles and the insulin

aggregates. Three measurements of the same sample were

performed for all the polystyrene beads and six measure-

ments for the polymer nanoparticles and protein aggregates.

The error bars displayed on the NTA graphs were obtained

by the standard deviation of the different measurements of

each sample. The mean size and SD values obtained by the

NTA software correspond to the arithmetic values calculated

with the sizes of all the particles analyzed by the software.

Live Monitoring of Protein Heat Stress

For the live monitoring of protein aggregation , the

above-mentioned IgG was formulated at a concentration of

1.0 mg/ml in 100 mM sodium citrate (Merck, Darmstadt,

Germany), pH 7.6. Unstressed IgG was inserted in the

NanoSight sample chamber at room temperature, and the

heating block was then set to 50°C. Once the chamber had

reached the set temperature, which took about 10 min, a

video was recorded for 40 s (t

0

), followed by three time points

with the same video length, at 15, 25 and 35 min. The videos

of the first three time points were captured with the “single

shutter and gain mode” and of the last time point with the

“extended dynamic range mode,” because of the high sample

polydispersity observed for this time point.

RESULTS AND DISCUSSION

Evaluation of NTA Performance and Comparison to DLS

Monodisperse Polystyrene Beads

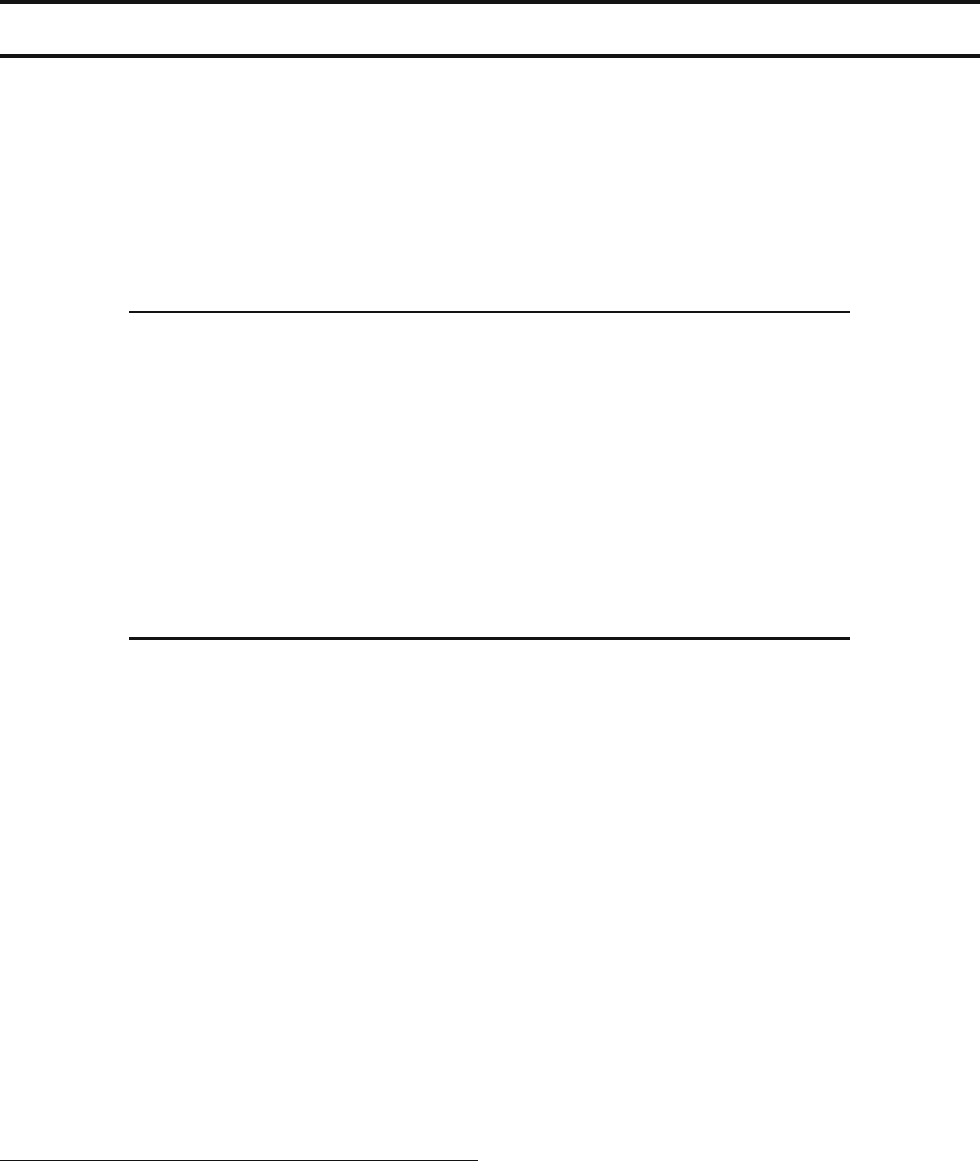

In order to verify the accuracy of NTA to size

monodisperse samples, standard polystyrene b eads of

60 nm, 100 nm, 200 nm, 400 nm and 1,000 nm were analyzed

with NTA, and the results were compared to DLS (Fig. 1).

While NTA requires particle concentrations of 10

7

–10

9

/ml,

the DLS concentration range is less critical and depends upon

a number of instrumental and sample properties ( 18). For

most of the samples used in this study, the DLS concentration

was about 10

8

–10

12

particles/ml (data not shown). Given the

798 Filipe, Hawe and Jiskoot

difference in concentration range between the two techniques,

a concentration suitable for both techniques was selected for

each bead size.

Contrary to DLS, NTA enables sample visualization and

provides approximate particle concentrations, which are very

useful features. Both techniques showed good sizing accuracy

and relatively narrow distributions for all monodisperse

samples. Nevertheless, it is possible to observe a tailing of

all DLS size distributions towards larger sizes, mostly due to

the immense contribution of a few large particles to the

overall scattering (14).

The mean size values obtained by NTA are slightly

smaller and closer to the expected values than the Z-ave

given by DLS, but all values are close to the bead size

specified by the manufacturer (Table I). However, the error

bars of the size distribution obtained for each sample are

smaller with DLS (Fig. 1), which is a consequence of the large

amount of statistical data collected by DLS when compared

to NTA. In fact, these high error bars in the NTA results are

mostly caused by different particle counts between each

measurement. The size distributions are practically the same,

but the software sometimes detects slightly more or slightly

less particles between each measurement of the same sample.

This variation in the number of particles detected by NTA

brings attention to the imprecision of the particle concentration

given by this technique. Still, though not the primary aim of

NTA, its capability to provide approximate submicron particle

counts is an obvious advantage of the method over DLS.

While DLS measurements are fast and rather straightfor-

ward, NTA requires several optimization steps by a skilled

operator, e.g. with respect to indentifying suitable settings for

the video capture and analysis. Whereas DLS can automati-

cally adjust the attenuator to adapt to a wide range of sample

concentrations, the search for the right sample concentration

for a successful NTA measurement can be time-consuming, as

it may require various dilution steps. However, NTA proved

to be slightly more accurate than DLS for sizing monodis-

perse samples.

Fig. 1. Size distribution from NTA and DLS measurements of monodisperse polystyrene beads. Error bars represent standard deviations

obtained from three measurements of the same sample.

Table I. Mean Size and Size Distribution of Monodisperse Polystyrene Beads from NTA and DLS Measurements

Bead size (nm)

DLS NTA

Z-ave (nm) PdI Mean (nm) SD (nm) Particle conc. (E8/ml)

60 68±1 0.04±0.01 66±2 20±1 7.70

100 112±4 0.13±0.07 105±6 30±10 1.87

200 218±1 0.04±0.01 200±5 30±5 2.32

400 443±5 0.13±0.03 394±7 62±6 1.08

1,000 1056±164 0.36±0.08 989±51 117±14 1.64

Z-ave Z-average; PdI polydispersity index; SD standard deviation calculated by the NTA software; Conc. concentration in particles E8/ml as

measured by NTA. Numbers represent average values ± standard deviation (n=3 measurements). See Materials and Methods for details.

799Critical Evaluation of Nanoparticle Tracking Analysis (NTA)

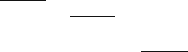

Mixtur es of Monodisperse Polystyre ne Beads: Fixed Number Ratio

One of the well-known pitfalls of DLS is its low peak

resolution, i.e. it can only resolve particle populations that

differ in size at least by a factor of 3 (19). Thus, with the

purpose of testing the resolution of NTA, the monodisperse

polystyrene standard beads analyzed in the previous section

were mixed at a fixed number ratio (60 nm and 100 nm; 100 nm

and 200 nm; 200 nm and 400 nm; 400 nm and 1,000 nm) and

analyzed with both techniques. The two-dimensional (2D) size

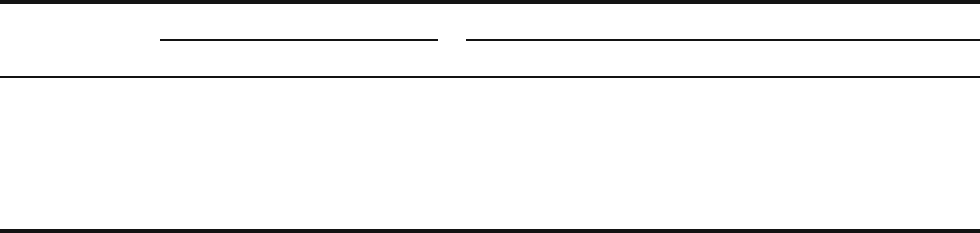

Fig. 2. Size distribution from NTA and DLS measurements of mixtures of monodisperse polystyrene beads (middle panels) with the corresponding

NTA video frame (left panels) and 3D graph (size vs. intensity vs. concentration; right panels). a) 60-nm/100-nm beads at a 4:1 number ratio; b) 100-

nm/200-nm beads at a 1:1 number ratio; c) 200-nm/400-nm beads at a 2:1 number ratio; d) 400-nm/1,000-nm beads at a 1:1 number ratio.

800 Filipe, Hawe and Jiskoot

distributions of DLS and NTA, with the corresponding NTA

video frames and three-dimensional (3D) graphs (size vs.

intensity vs. concentration) are shown in Fig. 2.

From these results, the difficulty of DLS in resolving

peaks of polydisperse samples becomes apparent, as it was

not possible to separate the two bead sizes of any of the

mixtures. On the other hand, NTA was able to resolve and

distinguish the two size populations in all mixtures and

yielded accurate size estimations of the beads in the mixtures

(Table II). The 2D size distributions show that DLS only

gives a single peak for the mixtures shifted towards the larger

particle size present, which is again related to its bias to larger

particles. The error bars of the DLS results of the two

mixtures with the larger bead size (Fig. 2c and d) are larger

than the ones of the NTA results. This is related to the

difficulty that the DLS software has to fit the data of an

autocorrelation curve of a sample that has two populations

with size differences smaller than the peak resolution limit of

this technique. As a result, the single peak as calculated by

the DLS software is prone to changes in shape and position

from measurement to measurement, giving rise to relatively

large error bars in the average result.

The two different bead sizes with different scattering

intensities can be observed in the NTA video frames and 2D

size distribution graphs and can be clearly distinguished in the

3D graphs (Fig. 2). Despite having a 60-nm/100-nm bead

number ratio of 4:1 (Fig 2a), NTA analysis of this mixture

shows more 100-nm beads than 60-nm beads. This is mainly

caused by a masking effect of the larger beads over the

smaller beads, explained in detail in the Influence of Small

Numbers of Large Particles section, combined with the fact

that some of the 60-nm beads move so fast that they often

move out of focus in the detection area before they can be

tracked long enough to be considered for the final result.

Nevertheless, the difference in scattering intensities displayed

by the 3D graphs proves to be very useful to confirm the

presence of different populations of similar sizes, such as in

this 60-nm/100-nm bead mixture. While the 2D graph shows a

peak at 100 nm and a shoulder at 60 nm, the 3D graph shows

two distinct size populations, clearly confirmed by the higher

light scattering intensity of the 100-nm particles compared to

the 60-nm ones. Thereby, the third dimension (scattering

intensity) in NTA contributes not only to the resolution of

particle populations, but also provides information about the

nature of the particles: for particles with equal refractive

index, the larger ones should scatter more light, proportional

to the diameter to the power six.

Measuring the mixture of monodisperse beads with DLS

is as easy and fast as measuring the standard polystyrene

beads alone, but the results do not reflect the samples’ real

content. On the other hand, NTA analysis of two different

particle sizes implies in most cases the use of the “extended

dynamic range mode,” which adds a complex variable to the

analysis. This mode allows the recording of a set of two

videos at the same time with different shutter and gain

settings, enabling the simultaneous analysis of large and small

particles in one measurement. A big advantage of NTA is the

unbiased high peak resolution for pol ydis perse samples,

which is not possible by DLS.

Mixtures of Monodisperse Polystyrene Beads: Effect

of Number Ratio

In the field of nanoparticle characterization, it is impor-

tant to have tools that are able to detect and characterize small

amounts of a certain particle size population, different from

the main population. Thus, to elucidate the ratio detection

limits of NTA, 100 and 400 nm polystyrene beads were mixed

at 100-nm/400-nm bead number ratios of 3:1, 6:1, 15:1, 150:1

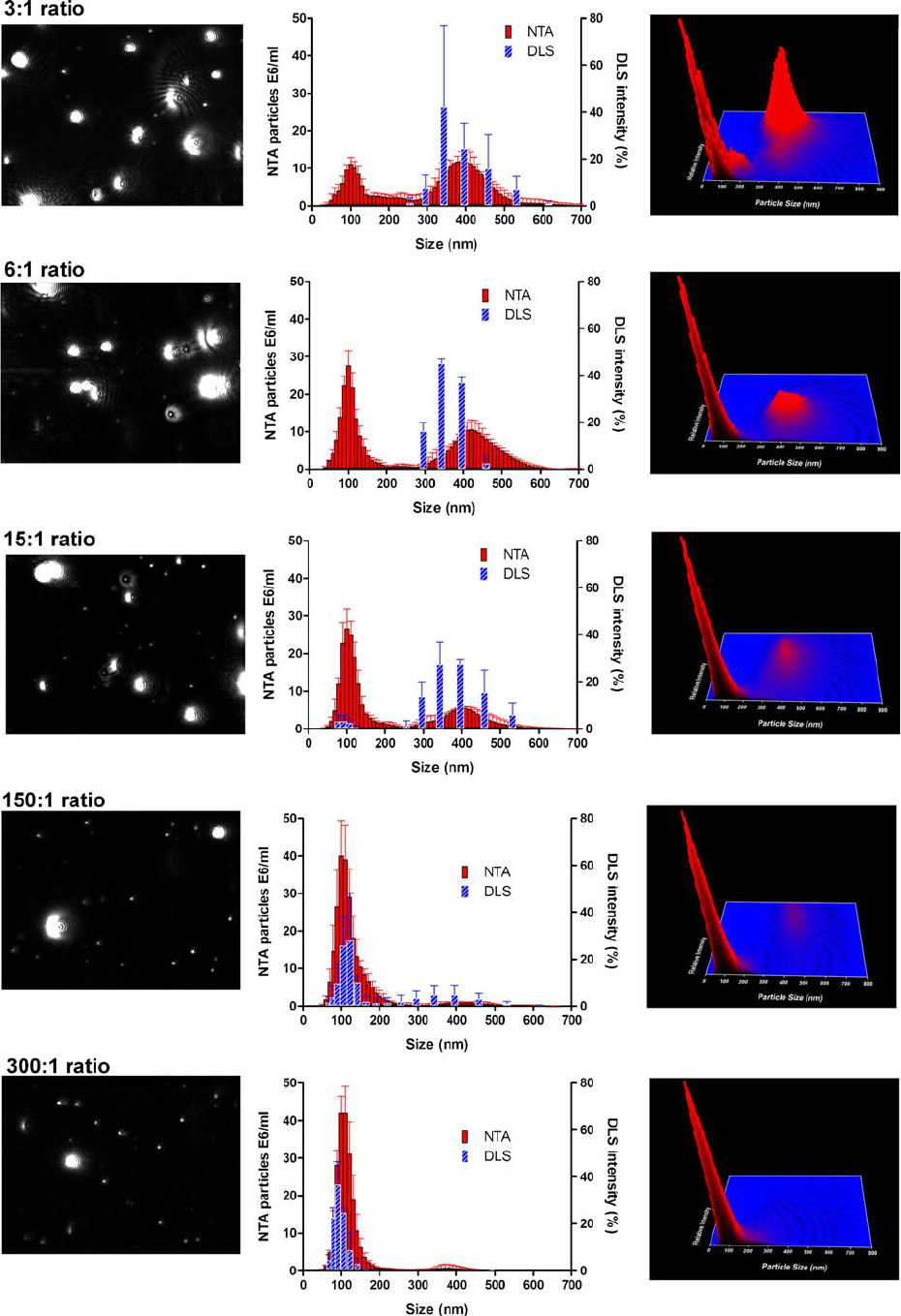

and 300:1, and analyzed with NTA and DLS (Fig. 3). The ratios

were based on the particle concentration of the individual bead

samples obtained by NTA.

The selection of the distinct sizes of beads for these

measurements took into consideration the DLS theoretical

peak resolution of 3:1 in size. Nonetheless, DLS was not able

to distinguish the two bead sizes for the lower 100-nm/400-nm

bead number ratios of 3:1 and 6:1, for which mainly the larger

beads were detected. When the number ratio reached 300:1,

the larger particles were no longer shown by DLS.

On the other hand, analysis with NTA enabled accurate

sizing and a clear distinction of the two size populations for all

the ratios analyzed. The presence of the two distinct size

populations is very clear in the video frames of Fig. 3. In fact,

being able to see the sample and search for the desired

location where the video is recorded enables the operator the

choice of including or excluding certain particles. Therefore,

the appearance of the 400 nm peak for ratios bigger than

300:1 depends on the operator. Being able to see and scan the

sample is a useful feature of NTA, but it should be used

prudently to avoid false or biased results.

Table II. Mean Size and Size Distribution of Mixtures of Monodisperse Polystyrene Beads from NTA and DLS Measurements

Bead size (nm)

DLS NTA

Z-ave (nm) PdI Peak (nm) Mean (nm) SD (nm) Peak 1 (nm) Peak 2 (nm) Peak 3 (nm)

60+100 84±1 0.08±0.01 83±7 90±3 33±4 58±4 91±9 –

100+200 195±2 0.40±0.20 194±5 162±13 60±6 98±2 196±2 –

200+400 347±42 0.19±0.03 359±32 298±20 122±9 195±5 410±10 –

400+1,000 952±31 0.26±0.05 912±75 712±36 296±20 427±46 1067±94 –

100+400 430±34 0.29±0.08 363±29 265±16 157±11 98±5 419±12 –

100+400+ S. Spike 467±22 0.35±0.05 378±32 338±36 163±23 99±10 384±12 850±83

100+400+B. Spike 698±26 0.14±0.07 750±65 527±101 353±11 106±4 420±22 997±31

Z-ave Z-average; PdI polydispersity index; SD standard deviation calculated by the NTA software; S. Spike small spike with 1,000-nm beads to

a 100-nm/400-nm beads mixture; B. Spike big spike with 1,000 nm beads to a 100 nm and 400 nm beads mixture. Numbers represent average

values ± standard deviation (n=3 measurements). See Materials and Methods for details. The peaks correspond to the highest value observed

for a certain size.

801Critical Evaluation of Nanoparticle Tracking Analysis (NTA)

802 Filipe, Hawe and Jiskoot

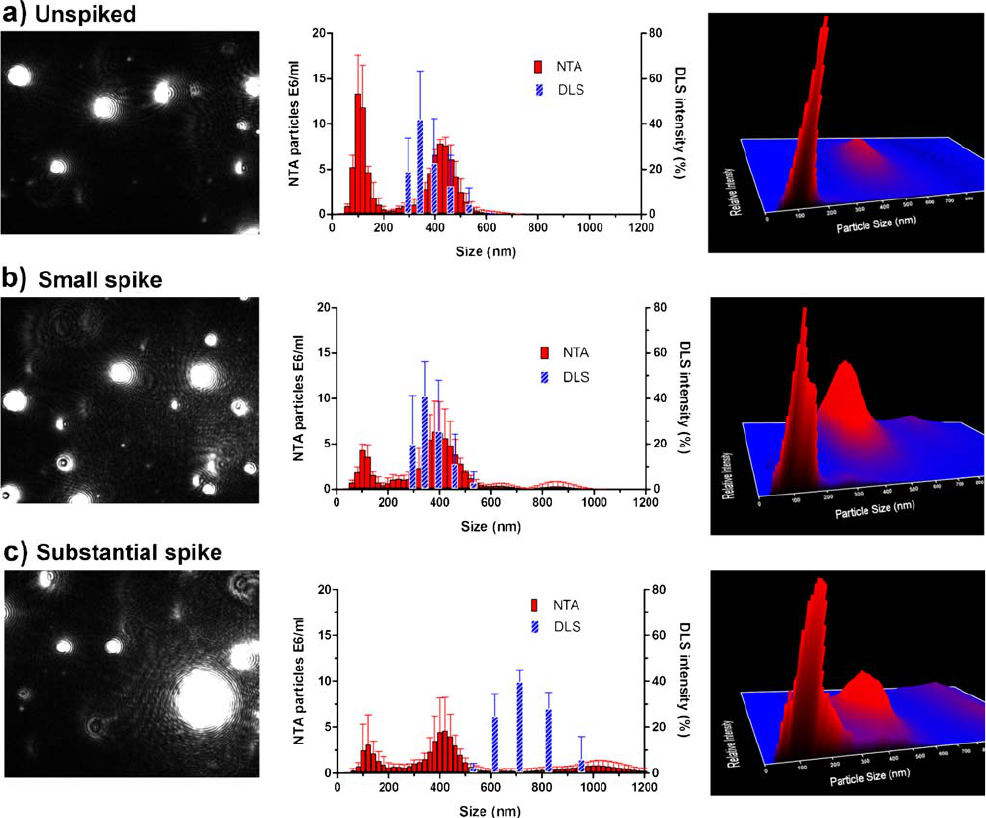

Influence of Small Numbers of Large Particles

One of the main concerns of DLS is the influence that a

small amount of large particles, such as dust, may have on the

outcome. The NTA technique is based on the tracking of

single particles, whereas DLS measures a bulk of particles

with a strong bias to the largest particles present in the

sample. Therefore, the performance of NTA is expected to be

less sensitive than DLS to the presence of minute amounts of

large particles. To compare the influence of large particles on

NTA and DLS results, a mixture of 100-nm and 400-nm

polystyrene beads was spiked with two different amounts of

1,000-nm beads. The resulting number ratios of 1,000-nm

beads to the beads in the initial mixture was 1:267 for the

small spike and 1:13 for the big spike (Fig. 4).

The small spike was sufficient to cause an increase of

about 40 nm in the Z-ave and of about 0.05 in the PdI

determined by DLS (Table II). The same spike made the

NTA analysis slightly more complicated because the highly

scattering 1,000-nm beads made the 100-nm beads slightly

more difficult to detect. However, with optimized settings

(Table III), all bead types present in the sample could be

detected and accurately sized by NTA (Fig. 4b). Nevertheless,

after the spike, the number of 100-nm beads detected by NTA

decreased by about 70% and the number of 400-nm beads by

about 20%. The intense light scattering of large particles

makes the small particles more difficult to detect and prevents

some of them from being tracked by the NTA software.

The big spike increased the Z-ave of DLS from 430 to

698 nm, but curiously decreased the PdI from 0.29 to 0.14.

Fig. 4. Influence of large particles (1,000-nm beads) in a mixture of 100-nm and 400-nm monodisperse beads on NTA and DLS measurements.

The size distribution (middle panels) with the corresponding NTA video frame (left panels) and normalized 3D graph (size vs. intensity vs.

concentration; right panels) are shown. a) no 1,000-nm beads; b) 1:267 number ratio of 1,000-nm beads to the other beads in the mixture; c) 1:13

number ratio of 1,000-nm beads to the other beads in the mixture.

Fig. 3. Influence of different number ratios of 100-nm/400-nm

monodisperse beads in NTA and DLS measurements (middle panels)

with the corresponding NTA video frame (left panels) and normalized

3D graph (size vs. intensity vs. concentration; right panels).

R

803Critical Evaluation of Nanoparticle Tracking Analysis (NTA)

Table III. Effect of the Most Important NTA Software Settings on Size Analysis

Parameter Description

Impact on the measurement

Incorrect settings Optimal settings

Shutter/Gain

a

Shutter determines length

of time camera shutter is open,

gain regulates sensitivity of

the camera

- Underexposed videos

omit smaller particles

All particles appear

as clear moving dots,

traceable by the software- Overexposed videos show

particles as untraceable wobbling light flares

Capture Duration Determines the length of the captured video - Too short videos result in inaccurate and

statistically poor size distributions

Statistically robust and

reproducible size distributions

Blur Smoothes captured video, eliminating

visual noise from around and within

the particle

- Excessive blur makes small particles disappear Removes false light scattering

centers, helps software

track real particles

- Insufficient blur leaves false light scattering centers

Detection Threshold

a

Determines minimum gray scale

value of a dot necessary for it to qualify

as a traceable particle

- Too high thresholds result in loss of small particles All particles in the video are

tracked, visual noise is

ignored

- Too low thresholds result in loss of large particles

or mistracking of visual noise

Minimum Expected

Particle Size (MEPS)

Determines area around the particle

where the software searches for it in

the following frame (large particles—slow

movements—small areas; small particles—

fast movements—large areas)

- Too high MEPS result in loss of small particles

because they move outside of the search area

Most particles in the video

are tracked long enough

to be included in final result- Too low MEPS result in loss of particles in

general due to search area overlap

a

Parameters that require thorough optimization and that have a major impact in the final outcome

804 Filipe, Hawe and Jiskoot

The lower PdI of this spiked sample is m ost likely a

consequence of the masking effect of the 1,000 nm beads over

the smaller beads in DLS measurements. These DLS values

could have suggested that it was a fairly monodisperse 700 nm

sample, when in fact it contained three distinct size populations

of 100, 400 and 1,000 nm. Such misinterpretation was not made

when using NTA, since the presence of different populations

was clearly detected by sample visualization. Although the big

spike made the NTA measurement s considera bly more

complex, all the beads in the sample could still be visualized

and accurately sized (Fig. 4c). However, also in this case, spiking

with large particles resulted in the underestimation of the

number of smaller beads. After this spike, the number of 100-

nm beads detected by NTA decreased by about 80% and that of

the 400-nm beads by about 35%.

Effect of Settings in NTA Software on Particle Size Data

As already mentioned, NTA involves several adjustment

steps during the video capture and analys is, which are

essential to obtain accurate measurement results. The power

of choice given to the operator may be seen as a great

advantage, but also raises concerns. The operator can easily

choose settings that ignore or emphasize the presence of

certain particles, which makes the veracity of the results

dependent on individual judgment and experience.

To obtain accurate results, one should (i) thoroughly

search with the microscope for the presence of all particle size

classes in the sample, (ii) optimize the video settings in order

to capture all these identified particle sizes, and (iii) adjust the

analytical settings to unbiasedly track all moving particles

captured by the video. With the purpose of clarifying the

weight of the different software settings on the result, the

influence of each param eter was carefully ana lyzed, as

summarized in Table III.

Since the quality of NTA data will be dependent on the

software settings used, which in turn depend on sample

properties, as well as on the experience and decisions of the

operator, NTA will be very difficult to qualify as a quality

control method. Instead, NTA is—like DLS—very useful as a

characterization tool, as will be demonstrated in the applica-

tions discussed below.

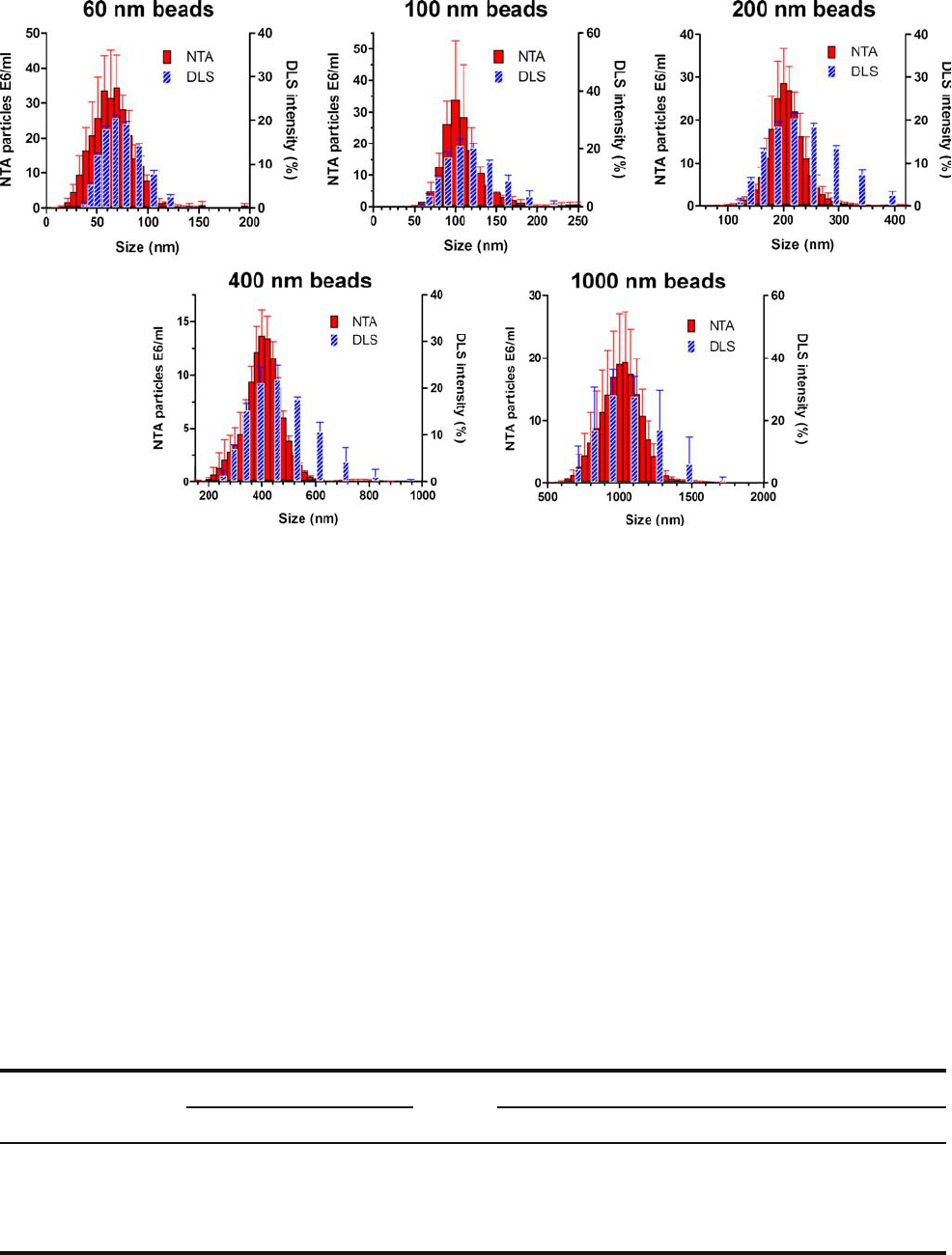

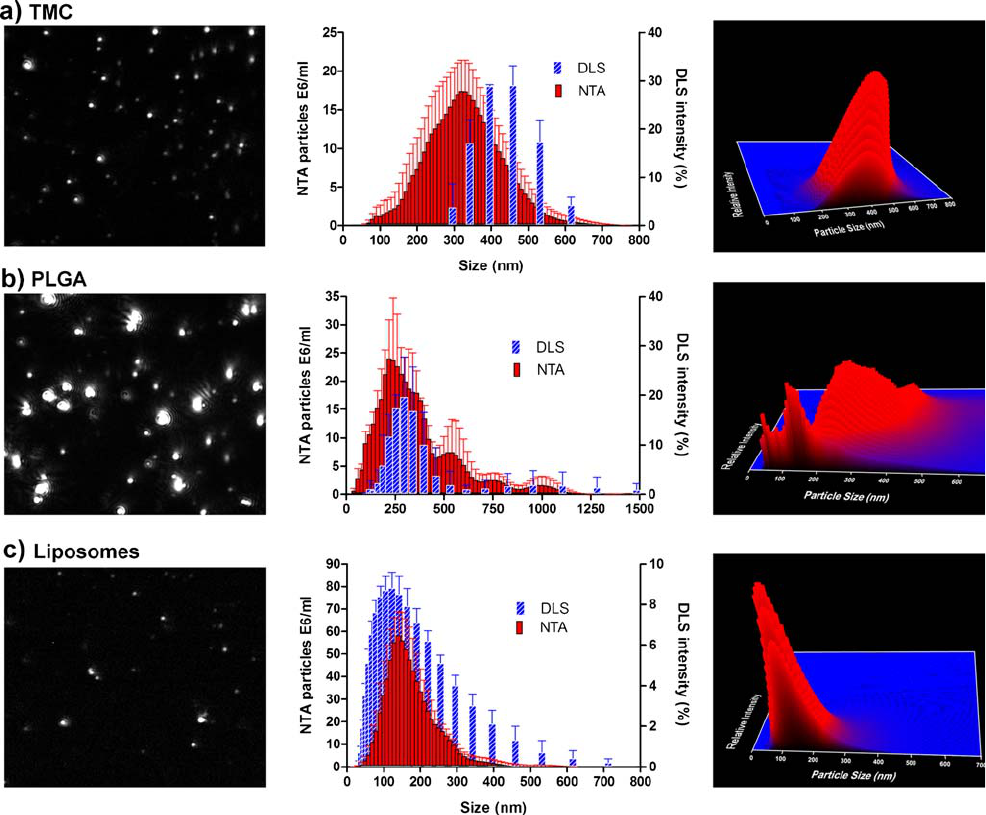

Fig. 5. Drug delivery nanoparticles measured with NTA and DLS. The size distribution (middle panels) with the corresponding NTA video

frame (left panels) and 3D graph (size vs. intensity vs. concentration; right panels) are shown.

805Critical Evaluation of Nanoparticle Tracking Analysis (NTA)

NTA Applications

Drug Delivery Nanoparticles

In order to evaluate the analytical performance of NTA

for nanoparticles commonly used in the pharmaceutical field,

PLGA particles, TMC particles and liposomes were analyzed

with NTA and the results compared to DLS (Fig. 5).

DLS analysis resulted in a Z-ave of 411 nm and a PdI of

0.09 for the TMC particles, indicating a relatively monodis-

perse sample. This was confirmed by the visualization of the

particles in the NanoSight sample chamber (Fig. 5a) and by the

relatively low standard deviation (91 nm) given by NTA.

However, the mean size obtained by NTA was 320 nm, which is

about 90 nm smaller than the Z-ave given by DLS, which

points to a certain degree of polydispersity. The systematic

size distribution shift towards larger sizes by DLS is more

accentuated for the TMC particles than for the monodisperse

polystyrene beads. This shift can be explained by the fact that

size distributions obtained by DLS are intensity distributions,

whereas NTA provides number distributions, which results in a

larger shift in case of higher polydispersity.

The PLGA particles analyzed by DLS exhibited a Z-ave

of 308 nm and a PdI of 0.22. This PdI value suggests that the

PLGA parti cles were more poly disperse than the TMC

particles. The relatively high polydispersity of the PLGA

particles became very clear during the visualization of the

sample by NTA (Fig. 5b) and was confirmed by the high

standard deviation (182 nm) obtained for the PLGA particles.

The main population of these particles given by DLS was

shifted to larger sizes as compared to NTA. However, contrary

to most samples analyzed in this evaluation, the mean value

observed with NTA (322 nm) was slightly higher than the Z-

ave given by DLS (Fig. 5). This may be due to the inherent

difficulty for DLS to properly analyze polydisperse samples.

DLS analysis of the liposomes resulted in a Z-ave of

117 nm and a PdI of 0.248, suggesting that this sample was

more polydisperse than the PLGA sample. Surprisingly, the

visualization of the liposomes with NTA revealed a fairly

monodisperse sample, and the standard deviation obtained

was 77 nm, which is even smaller than that of TMC particles.

The mean size value obtained with NTA was 154 nm, which is

again larger than the Z-ave given by DLS. This time the peak

given by DLS is shifted to smaller sizes as compared to the one

obtained by NTA. Given that DLS has a lower detection limit

than NTA, it is possible that smaller particles (<30 nm) present

in the formulation decreased the Z-ave in DLS, which would

also explain the relatively high PdI. Other analytical tech-

niques would have been necessary to clarify this observation.

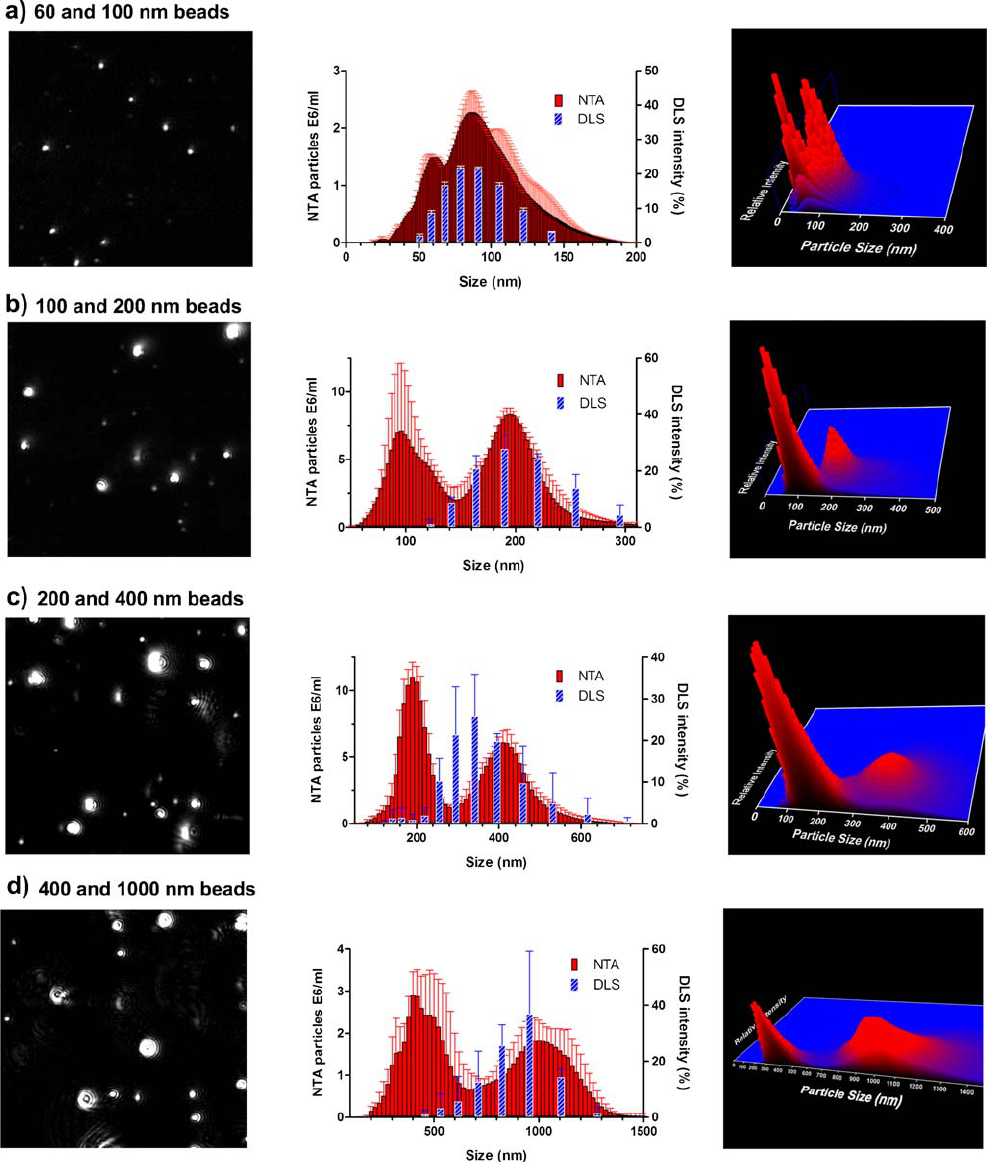

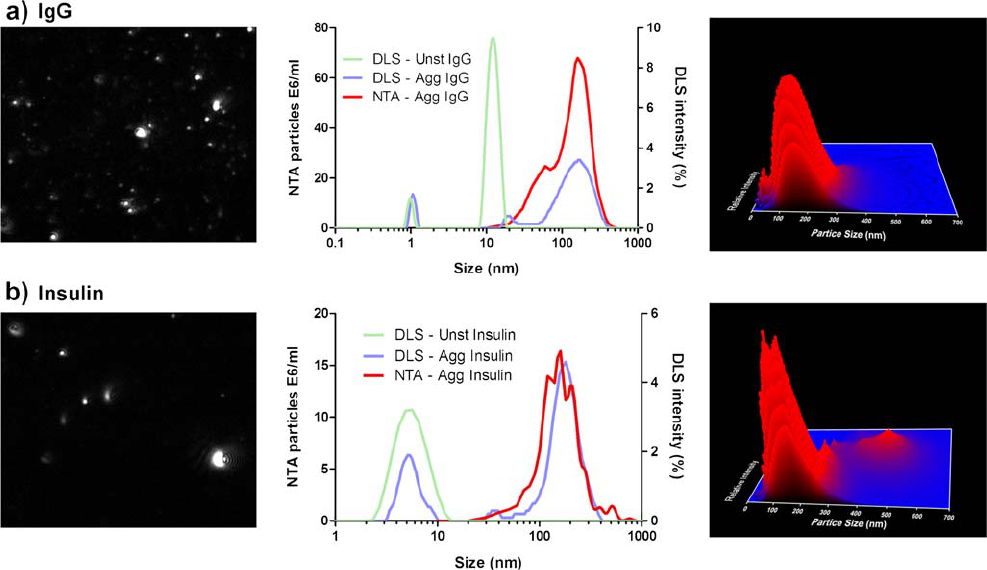

Protein Aggregates

A heat-stressed IgG formulation and a metal-oxidized

insulin formulation were used to evaluate the analytical

performance of NTA with protein aggregates (Fig. 6). The

difference in the lower detection limits of the two techniques

was evident when it came to the characterization of protein

aggregates. DLS was able to detect not only the monomeric

IgG (∼11 nm) but also the sucrose molecules (∼1 nm) present

in the buffer, as was earlier described by others (20,21). Given

that the lower detection limit of NTA for proteins is about

30 nm, protein monomers and aggregates smaller than this

Fig. 6. IgG aggregates (obtained by heat stress) and insulin aggregates (obtained by metal catalyzed oxidation) measured with NTA and DLS.

The size distribution (middle panels) with the corresponding NTA video frame (left panels) and 3D graph (size vs. intensity vs. concentration;

right panels) are shown.

806 Filipe, Hawe and Jiskoot

are not detected by this technique. Nevertheless, in the

stressed IgG formulation, the IgG aggregate size distribution

obtained by DLS and NTA was similar, with a main peak at

around 200 nm. The Z-ave obtained by DLS was 47 nm and

the PdI 0.5, while the average size according to NTA was

175 nm and the standard deviation 76 nm. The difference in

the mean size values is most likely due to the fact that DLS

considers aggregates, monomer and sucrose for the Z-ave

(also explaining the high PdI), while NTA considers only

aggregates for calculating the mean particle size (Fig. 6a).

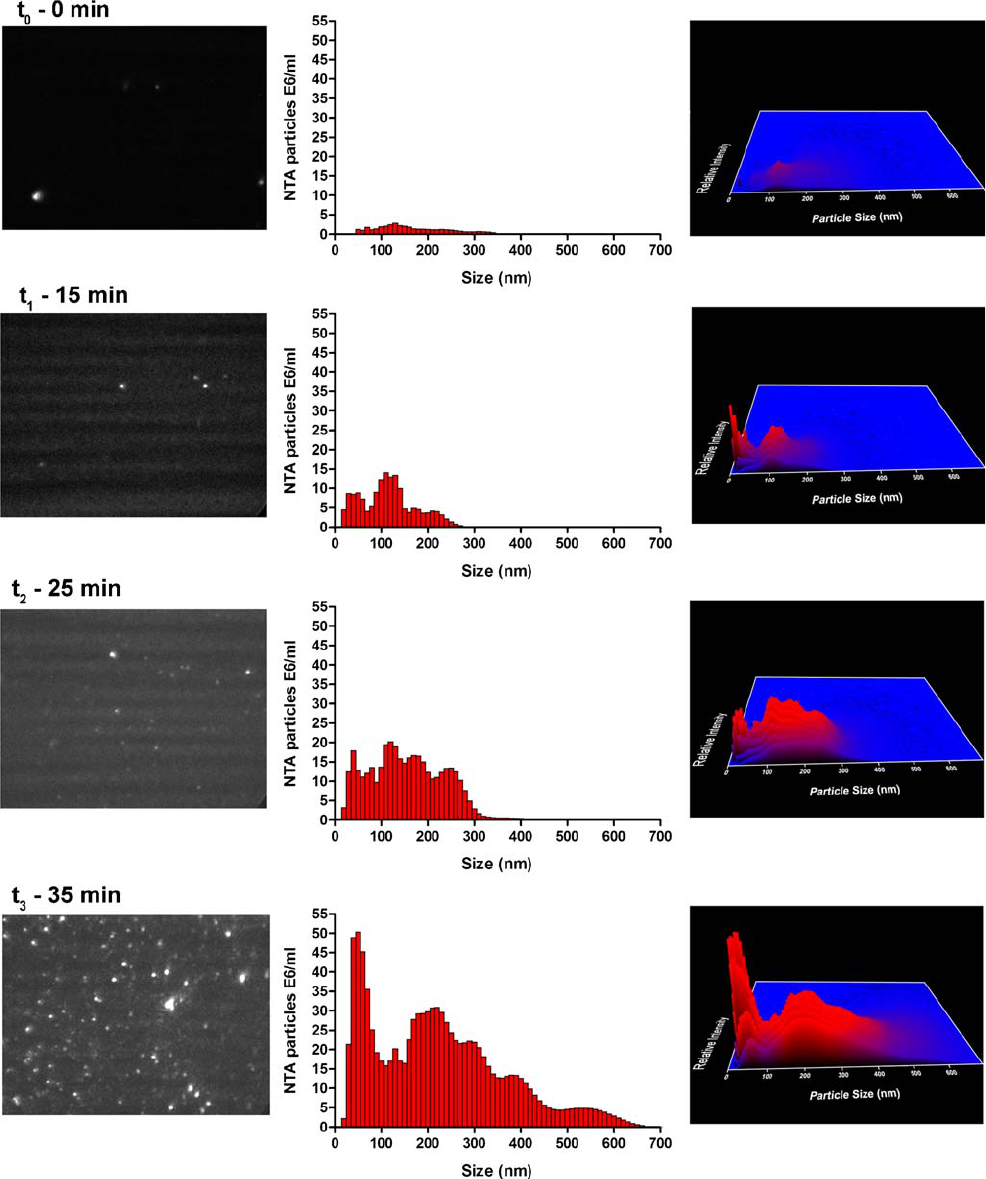

Fig. 7. Live monitoring of IgG aggregation at 50°C in the NanoSight sample chamber. The size distribution (middle panels) with the

corresponding NTA video frame (left panels) and 3D graph (size vs. intensity vs. concentration; right panels) are shown.

807Critical Evaluation of Nanoparticle Tracking Analysis (NTA)

The visualization of the aggregated IgG sample with

NTA allowed the distinction of two or more light

scattering centers in very large aggregates (>1 μm), which

suggests that they were formed by the assembly of

smaller aggregates. However, the brightness of such large

particles interferes with the optimization of the instru-

ment settings, because it makes smaller aggregates more

difficult to detect. The monomer present in the sample

increases the background light and also makes smaller

aggregates more difficult do detect.

In the aggregated insulin sample, the native insulin

was only detected by DLS and found to have an average

size of about 6 nm, consistent with literature data for

insulin at neutral pH (22).Alsoforthissample,the

aggregate size distribution was consistent between the

two techniques, with a broad peak centered around

160 nm (Fig. 6b). The Z-ave given by DLS was 70 nm

and the PdI 1.0, while the mean given by NTA was

199 nm and the standard deviation 103 nm. Such a high

PdI given by DLS suggested that the aggregates in the

sample were very polydisperse, which can be confirmed

by sample visualization and high standard deviation

provided by NTA. Once again, the difference in mean

value and Z-ave given by the two techniques is most

likely due to the fact that DLS considers native insulin

and aggregates, while NTA considers only aggregates.

Table IV. Comparison of NTA with DLS

DLS NTA

Characteristics

Size accuracy Accurate for monodisperse samples, inaccurate

for polydisperse samples

Accurate for both monodisperse and

polydisperse samples

Peak resolution Low (>3 fold difference in diameter) High (<0.5 fold difference in diameter)

Size range Ca. 1–1,000 nm Ca. 30–1,000 nm

Concentration range (particles/ml) Broad (about 10

8

–10

12

) Limited (10

7

–10

9

)

Population ratio Narrow range Very broad range

Large influence on size accuracy and distribution Very little influence on size accuracy and

little influence on size distribution

Reproducibility More reproducible Less reproducible

Contaminations Large particles can seriously compromise the results Dust, microorganisms or aggregates

easily detected, large particles have

little influence

Operational

Device handling Very user-friendly Requires several parameter adjustments

Little sample handling Sample handling may affect size distribution

Possibility of using disposable cuvettes Sample chamber must be cleaned after each

sample

Experienced operator required

Time consumption Between 2 to 5 min per measurement Between 5 min to 1 hour per measurement

Particular output Approximate size distribution Individual particle sizing

Intensity distribution Number distribution

Z-ave Approximate concentrations

PdI Individual particle intensity

Sample visualization No Yes

Applications

Drug delivery nanoparticles Accurate sizing Accurate sizing

Approximate size distribution More reliable size distribution

Hard detection of contaminants Easy detection of contaminants

Protein aggregates Approximate size distribution Accurate size distribution

Includes protein monomers and some

excipients

Protein monomer and small aggregates

excluded

Presence of very large aggregates has a

big impact on the result

Aggregate architecture information

Interference of large aggregates may

sometimes be overcome

808 Filipe, Hawe and Jiskoot

Several factors are known to induce protein aggregation,

and some characterization techniques have been reported to

induce or disturb the aggregation state (8). During NTA

measurements, the sample is in contact with glass, stainless

steel, a Viton fluoroelastomer O-ring and nylon tubing.

Moreover, the samples are submitted to a slight shear during

the injection into the measurement cell. It has been reported

that the synergistic effect of adsorption of a monoclonal

antibody to stainless steel and shear can create small amounts

of aggregates (23). In fact, we noticed that some stressed IgG

formulations slightly increase the amount and size of aggre-

gates if left in the sample chamber for more than 30 min (data

not shown). This phenomenon became more evident if the

sample was moved back and forth in the measurement cell

with the syringe piston. While DLS size measurements are

usually performed in disposable (polystyrene) cuvettes, the

NanoSight sample chamber has to be manually cleaned and

reused. Furthermore, as previously mentioned, NTA mea-

surements often require sample dilution, which may destroy

or create new aggregates and affect the size distribution

(8). In general, the effect of sample content dilution on the

sample content is related to the instability of the submicron

particles and is more likely to affect protein aggregates

than drug delivery nanoparticles.

Overall, DLS sample treatment seems to be less aggres-

sive than NTA, which is an advantage for unstable samples,

such as protein aggregates. However, the high peak resolu-

tion and suitability for polydisperse samples make NTA a

very useful technique to analyze protein aggregates.

Live Monitoring of Heat-Induced Protein Aggregation

The heating block of NanoSight allows NTA measure-

ments at temperatures ranging from room temperature to

50°C, which enables the live monitoring of protein aggrega-

tion at elevated temperatures. This feature is also possible

with DLS, but the possibility of visualizing the aggregates

being formed with NTA gives a more complete overview of

the aggregation process.

An IgG formulation was heated at 50°C for 45 min in the

NanoSight heating block, while movies were being recorded

(Fig. 7). Since NTA is not capable of detecting particles

smaller than about 30 nm, it was not possible to see the

formation of dimers, trimers or any small oligomers. At t

0

, the

sample had already been exposed to some heat stress for

about 10 min, the time required for the temperature to rise

from room temperature to 50°C, and some polydisperse

aggregates of about 50–350 nm were detected. At t

1

, the

number of aggregates had increased, and distinct subpopula-

tions became apparent around 50 nm, 100 nm and 200 nm.

After about 20 min, t he number of a ggregates rapidly

increased. Even though the number of aggregates had slightly

increased at t

2

, it does not reflect this sudden increase of

aggregates observed, because the background scattering

(visible in the video frame of t

2

) made particle tracking more

difficult for the NTA software. After 35 min of heat-stressing,

the number of aggregates reached the upper concentration

limit of NTA, and especially the number of aggregates with

sizes around 50 nm increased significantly. After 45 min, very

large (>5 μm) aggregates wer e visible, and they made

accurate NTA size measurements impossible, because the

light they scattered masked the smaller traceable aggregates

(<1 μm). These large aggregates contained several intense

lig ht scattering centers (results not shown), which were

probably formed by the assembly of several smaller aggre-

gates. Unfortunately, aggregate assembly process was not

detectable by this technique, since the aggregates were

constantly entering and leaving the view area.

CONCLUSIONS

In this work, we evaluated NTA as a new character-

ization method for nanoparticle analysis and compared it to

DLS. The differences between the two techniques are

summed in Table IV. NTA can be time-consuming and

requires some operational skills for the adjustment all

software settings, but has some clear advantages over DLS.

NTA enables the visualization of the sample, gives an

approximate particle concentration and obtains size informa-

tion based on the Brownian motion of individual particles.

NTA is very accurate for sizing both monodisperse and

polydisperse samples and has a substantially better peak

resolution. The presence of few large particles in a sample has

a little impact on NTA sizing accuracy, but reduces the

number of small particles detected by the software. Different

population ratios in standard polystyrene bead mixtures are

easily detected and do not affect the sizing accuracy.

NTA proved to be very suitable for analyzing drug

delivery nanoparticles. This technique is also very suitable for

analyzing protein aggregates, but care should be taken that

sample preparation does not influence the aggregate distri-

bution in the measurement cell. It also gives the possibility of

live monitoring heat-induced aggregation, providing informa-

tion about the aggregation kinetics.

AKNOWLEDGEMENTS

This research is supported by the Dutch Technology

Foundation STW, applied science division of NWO and the

Technology Program of the Ministry of Economic Affairs.

The authors are grateful to Bram Slütter and Ana Silva for

the preparation of the TMC n anoparticles and PLGA

particles, to Myrra Cars tens for the preparati on of the

liposomes and to Riccardo Torosantucci and Olubukayo

Oyetayo for preparing the aggregated protein samples.

Open Access This article is distributed under the terms of the

Creative Commons Attribution Noncommercial License, which

permits any noncommercial use, distribution, and reproduction in

any medium, provided the original author(s) and source are credited.

REFERENCES

1. Mahato RI, Narang AS, Thoma L, Miller DD. Emerging trends

in oral delivery of peptide and protein drugs. Crit Rev Ther

Drug Carrier Syst. 2003;20:153–214.

2. Lipinski CA. Drug-like properties and the cau ses of poor

solubility and poor permeability. J Pharmacol Toxicol Meth.

2000;44:235–49.

809Critical Evaluation of Nanoparticle Tracking Analysis (NTA)

3. J iskoot W, van Schie RM, Carstens MG, Schellekens H.

Immunological risk of injectable drug delivery systems. Pharm

Res. 2009;26:1303–14.

4. Cromwell ME, Hilario E, Jacobson F. Protein aggregation and

bioprocessing. AAPS J. 2006;8:E572–9.

5. Schellekens H. Bioequivalence and the immunogenicity of

biopharmaceuticals. Nat Rev Drug Discov. 2002;1:457–62.

6. Mahler HC, Friess W, Grauschopf U, Kiese S. Protein aggrega-

tion: pathways, induction factors and analysis. J Pharm Sci.

2009;98:2909–34.

7. Frokjaer S, Otzen DE. Protein drug stability: a formulation

challenge. Nat Rev Drug Discov. 2005;4:298–306.

8. Philo JS. A critical review of methods for size characterization of

non-particulate protein aggregates. Curr Pharm Biotechnol.

2009;10:359–72.

9. Carpenter JF, Randolph TW, Jiskoot W, Crommelin DJ, Middaugh

CR, Winter G, et al. Overlooking subvisible particles in therapeutic

protein products: gaps that may compromise product quality. J

Pharm Sci. 2009;98:1201–5.

10. Bootz A, Vogel V, Schubert D, Kreuter J. Comparison of

scannin g electron microscopy, dynamic light scattering and

analytical ultracentrifugation for the sizing of poly(butyl cyanoa-

crylate) nanoparticles. Eur J Pharm Biopharm. 2004;57:369–75.

11. Brown PH, Schuck P. Macromolecular size-and-shape distribu-

tions by sedimentation velocity analytical ultracentrifugation.

Biophys J. 2006;90:4651–61.

12. Fraunhofer W, Winter G, Coester C. Asymmetrical flow field-flow

fractionation and multiangle light scattering for analysis of gelatin

nanoparticle drug carrier systems. Anal Chem. 2004;76:1909–20.

13. Frisken BJ. Revisiting the method of cumulants for the analysis

of dynamic light-scattering data. Appl Opt. 2001;40:4087–91.

14. Demeester J, Smedt S , Sanders N, Haustraete J. Light

Scattering. In: Jiskoot W, Crommelin DJ, edito rs. Methods for

structural analysis of protein p harmaceuticals. Arlington:

AAPS; 2005.

15. Berne B, Pecora R. Dynamic light scattering with applications to

chemistry, biology, and physics. Mineola: Dover; 2000.

16. Applications of Nanoparticle Tracking Analysis (NTA) in Nano-

particle Research. http://www.schaefer-tec.com/fileadmin/user_

upload/sort iment/nanopartikel/NanoSight/NANOSIGHT_Appli

catio n_Review_NTA_April_2009_M201B.pdf (accessed 26/09/

2009), part of NanoSight. http://www.nanosight.co.uk (accessed

26/09/2009).

17. Slutter B, Plapied L, Fievez V, Sande MA, des Rieux A,

Schneider YJ, et al. Mechanistic study of the adjuvant effect of

biodegradable nanoparticles in mucosal vaccination. J Control

Release. 2009;138:113–21.

18. Minimum DLS concentration? http://www.malvern.com/malvern/

kbase.nsf/allfaqbyno/KB000795?opendocument (accessed 22/09/

2009), part of Malvern support FAQ. http://www.malvern.com

(accessed 22/09/2009).

19. Can DLS resolve oligomer mixtures? http://www.malvern.com/

malvern/kbase.nsf/allfaqbyno/KB001102 (accessed 22/09/2009),

part of Malvern supp ort FAQ. http://www.malvern.com

(accessed 22/09/2009).

20. Mahler HC, Muller R, Friess W, Delille A, Matheus S. Induction

and analysis of aggregates in a liquid IgG1-antibody formulation.

Eur J Pharm Biopharm. 2005;59:407–17.

21. Kaszuba M, McKnight D, Connah MT, McNeil-Watson FK,

Nobbmann U. Measuring sub nanometre sizes using dynamic

light scattering. J Nanopart Res. 2007;10:823–

9.

22. Hvidt S. Insulin association in neutral solutions studied by light

scattering. Biophys Chemist. 1991;39:205–13.

23. Bee JS, Stevenson JL, Mehta B, Svitel J, Pollastrini J, Platz R, et

al. Response of a concentrated monoclonal antibody formulation

to high shear. Biotechnol Bioeng. 2009;103:936–43.

810 Filipe, Hawe and Jiskoot